To comply with the requirements of the Medical Device Directive, the chosen Sterility Assurance Level (SAL) of product requires validation. Sterilisation validation is carried out by MVS in accordance with ISO 11137 and includes bacteriostasis and fungistasis testing using harmonised pharmacopoeia recommended organisms

Expert advice in relation to Method VDMax and Dose Setting exercises can be given on product grouping, determining master product, complex packs and test frequencies. Our sample submission form (click here) gives information on how many samples are required for each exercise.

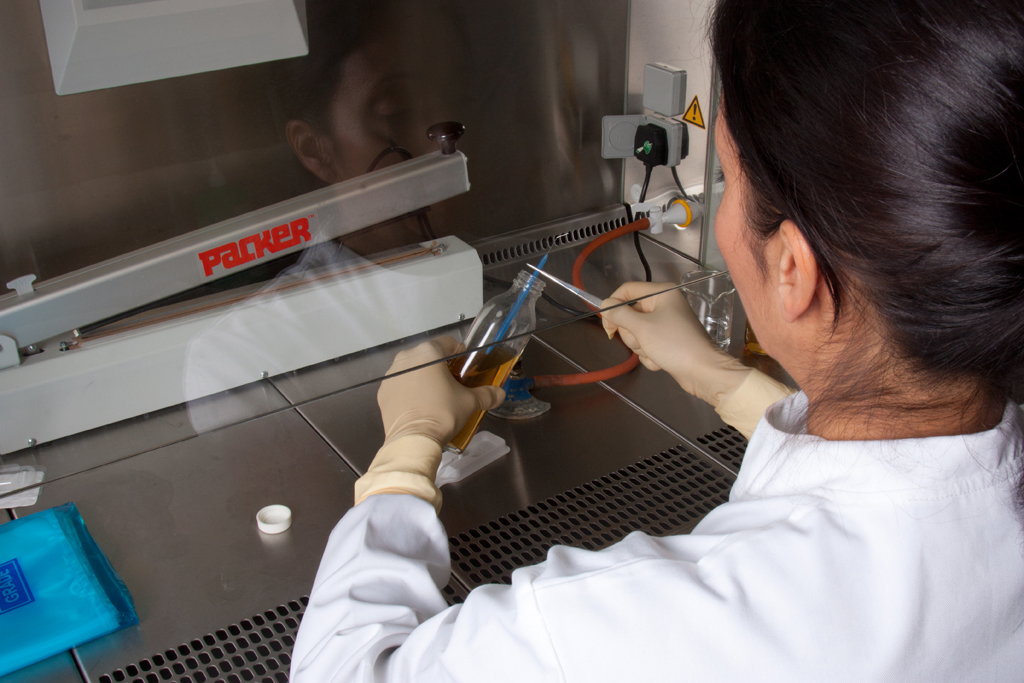

Sterility testing is carried out by highly skilled and validated technicians, in a Class A laminar air flow cabinet within a Class B cleanroom, or within a dedicated laboratory in a Class II Safety Cabinet.

Testing can either be carried out by membrane filtration or direct inoculation.

Additional areas of sterilisation validation include accelerated ageing, and sterility testing to confirm pack integrity for all methods of sterilisation. MVS have the skills and expertise to advise upon all methods of sterilisation including Gamma and E-beam irradiation, Ethylene Oxide, Steam Sterilisation and other novel methods.